Passive acting explosion valves (FIKE’s Ventex i Valvex) manages with explosion at a relatively small section of a plant. The destructive force of blast wave do not get through other locations. Performance of insulation/decoupling system is simple and efficient, either. It’s activated by explosion itself.

Any transmitters and controlling units are not required, blast wave pushes ball lock, which is urged by a spring. The mechanism closes cross section permanently then. The nominal pressure is set to be exceeded only by explosion force.

The speed of Ventex and Valvex reaction is of order of milliseconds. However, insulation systems should co-operate with others units (rupture panels, HRD type suppression systems, SRD type decoupling systems). Solutions of suppression and offloading are of the same importance, in order to limit the explosion diffusion.

CORONA, as FIKE’s authorized representative in Poland, offers wide range of explosion insulating and decoupling valves. We offer one and two way valves, also special ones, enabling its placing at low distance from possible explosion foci.

We ensure a design and assembly with further servicing.

PRODUCTS

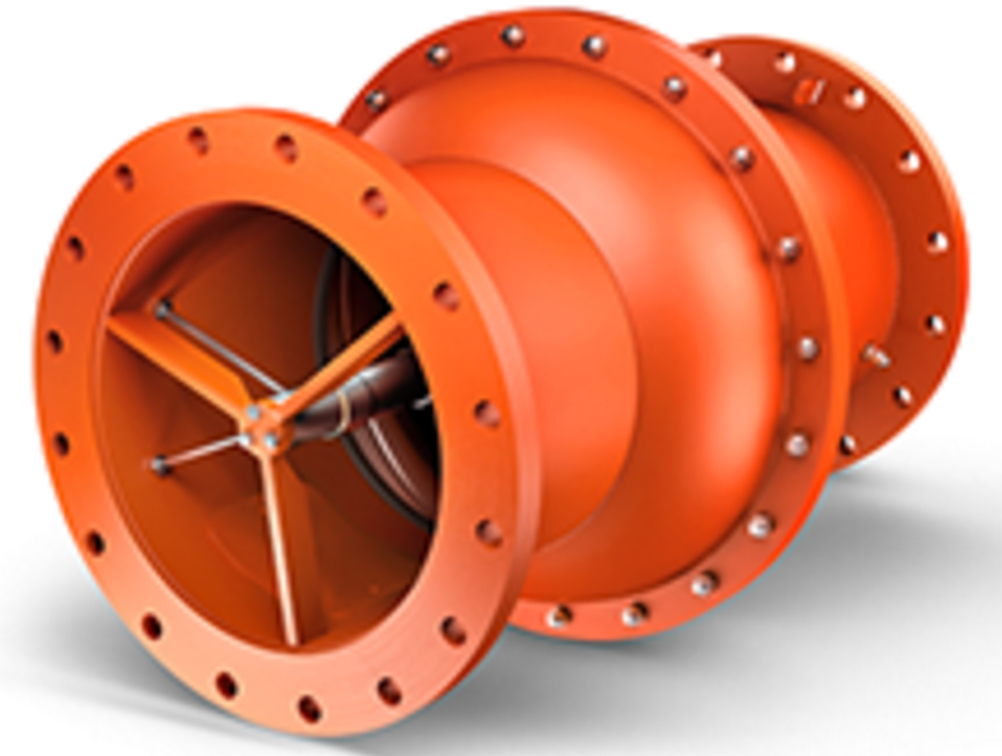

It is a mechanical valve, designed to protect against fire and pressure propagation through pipelines, lines to other elements of installations.

Ventex passive acting valves, provided by FIKE, are able to close rapidly every explosion, at short distance. The destructive force of blast wave do not get through other locations.