At almost every branch of modern industry polymeric materials are used. They undergo wearing while exploating, so maintenance is conducted. A significant load of knowledge is involved to recognize the type of polymeric material, due to select adequate solvent, glue or lacquer for processing stage. In the case of total destruction, materials are disposed of, which involves a huge amount of wastes – from disposable packagings, to everyday life objects and machinery or constructional parts.

A special solution for transformation of polymeric materials has been developed, as they don’t decay rapidly. Also a landfill site are of limited capacity. The solution is pelletizing system.

A granulate of artificial materials is widely applied in many processing plants, where single screw extruder plasticizing systems are involved (equal rods of polymeric materials are obtained).

As far as pelletizing system is concerned, rheological and thermal properties, efficiency of electricity consumption, process reliability, further performance of granulate and durability of device must be considered.

PRODUCTS

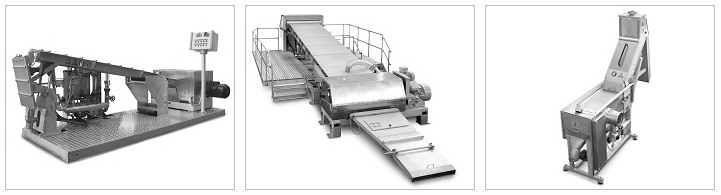

SPHERO® is an underwater pelletizing system designed for all kinds of thermoplastic materials, characterized by high flexibility and a small footprint. The system produces spherical pellets of superb quality, ideally suited for further processing with throughputs up to 36,000 kg/h.

M-USG - Underwater Strand Pelletizing Systems. The M-USG underwater strand pelletizing systems are especially designed for medium up to the highest production capacities.

The WSG water bath strand pelletizing systems with PRIMO E, PRIMO S, PRIMO PLUS, BAOLI, BAOMO or M-ASG pelletizers produce the highest quality of cylindrical pellets or micro pellets, ideally suited for further processing. PRIMO-S - rugged strand pelletizer PRIMO PLUS - for the sophisticated production of high value compounds, blends and masterbatches.

The DROPPO® drop pelletizing system from Maag Automatik is designed to produce uniform dust-free spherical pellets. The cooling and solidification process may use air, nitrogen or water – thus offering maximum flexibility to the customer.

Efficient granulation drying technology for many applications

Whether for complete high-performance production systems, small machines for lab applications or anything in between, Maag Automatik tailors solutions to meet exact customer requirements and preferences. The Maag Automatik product lines comprise: