PRODUCTS

ACTIVE SYSTEM OF EXPLOSION SUPPRESSION HRD TYPE (HIGH RATE DISCHARGE). CORONA offers wide range of technical consultancy and designing of explosion-proof protection system, calculation and supplying with assembly and later maintenance. Also we offer servicing (we are disposing a warehouse of replacement parts, available 24/7)..

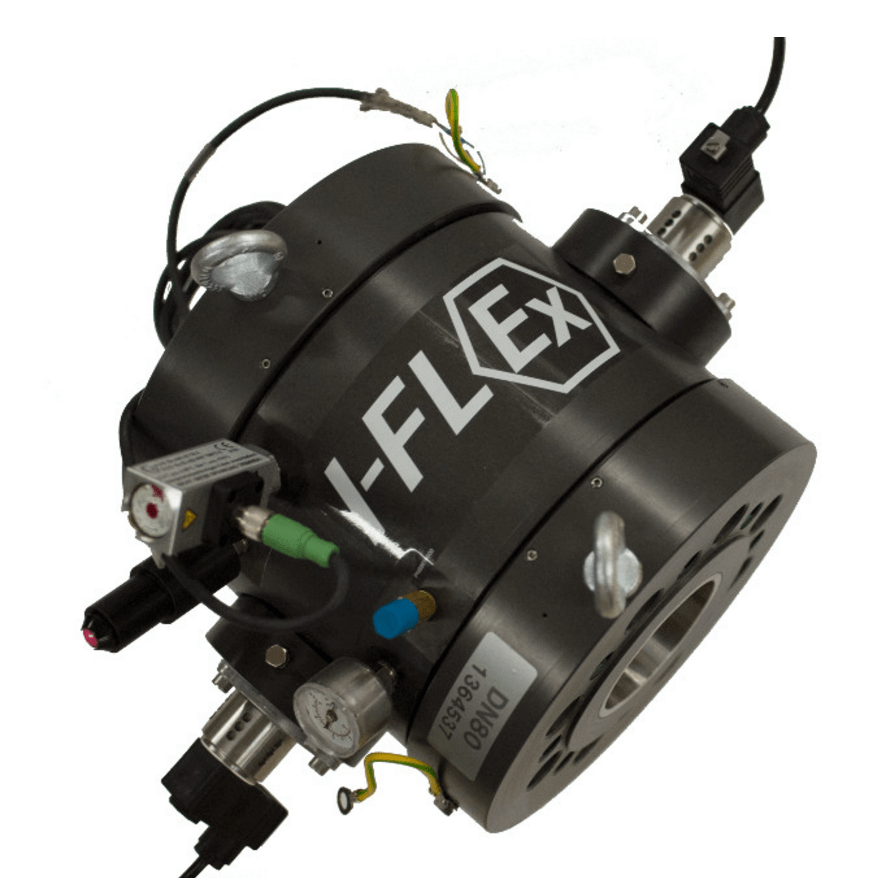

INSULATION OF EXPLOSION AIMS AT EXPLOSION PROPAGATION PREVENTION When a blast wave shifts towards installation, a powder is released. Its task is to create a cutting off barrier which prevents from fuel contacting with air and then explosion propagation.

A VALVE ACTS THROUGH COMPRESSED AIR INSUFFLATING, WHAT PROVIDES PIPE CROSS-SECTION TIGHTENING, SO THE EXPLOSION CANNOT SPREAD. Insulating/decoupling safeguard unit is activated by overpressure or optical detection and panel rupture, equipped with rupture sensor.

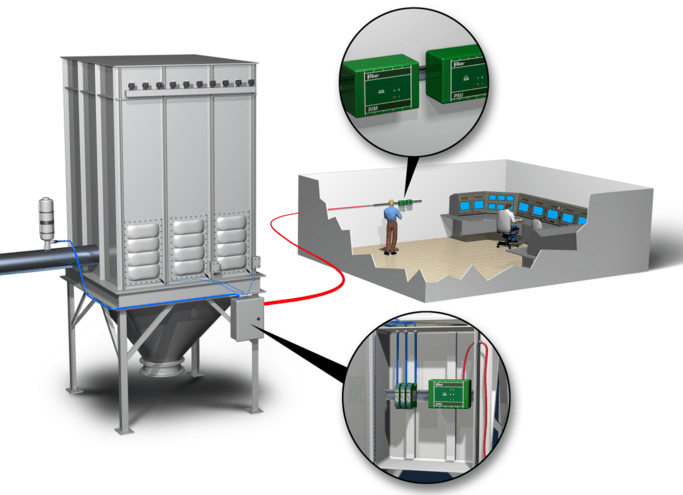

Unit employed with active suppression and decoupling systems. Control cabinet, accordingly to configuration, is characterized by appropriate SIL degree of reliability and additionally is allowed by FM Global group.

WYKRYCIE WYBUCHU W JEGO WCZESNEJ FAZIE I PRZEKAZANIE DO CENTRALKI.

DEFLAGRATION DETECTION AT THE VERY BEGINNING AND PASSING THE INFORMATION TO THE CONTROLLING UNIT.

Transmits hazardous dust concentration. Detects raised dust concentration, due to filtration’s bag perforation and prevents the emergence of a hostile environment. Fans Ex implementation is also available.

In Poland, official representative of Fike is CORONA Sp. z o.o. The most recognized Fike products are rupturę panels and bursting disc (explosion offloading), active protection systems against explosion (HRD/SRD) and passive – such as flame quenchers (flameless offloading) or other modern solutions as pinch valves or fast activating valves. Common feature of all the equipment is, beside increasing the level of safety, significant increase of economic aspects – lowering the exploitation costs.

CORONA company offers delivery, full servicing all FIKE’s units. Products have all needed approvals and certificates, ATEX included.